Efficient catalog production at Schmidt's with crossbase

The Schmidts Group uses the crossbase solution to optimize the management of over 200,000 articles and 42,000 media assets as well as the production of print and online media. Thanks to a high level of automation, an inheritance concept and dynamic hyperlinks, maintenance effort and production times have been significantly reduced, while efficiency has been increased.

We were able to successfully merge our two existing systems into crossbase. With this modern tool we can deliver media-compatible output for all channels and are ready for future requirements.

Kurt Wohlgenannt

CIO, Head of IT and Logistics, Authorized Signatory, Schmidt’s Handelsgesellschaft mbH

Initial situation

Currently, over 200,000 articles are continuously transferred from the ERP system to the crossbase database via the XML interface. There, the data is structured, enriched with additional content and prepared for output in print and online media. Most product information is maintained at master product level. For this reason, the inheritance concept is used, which "inherits" defined content to the subordinate levels and thus minimizes the maintenance effort. In addition, some of the data maintained in crossbase is returned to the ERP system via the API interface so that the data is always identical.

Procedure

The Schmidts Group's existing store systems are connected via the crossbase API server and obtain content such as product features, texts and images from the crossbase database. Over 2,000 product features are managed in around 700 attribute classes for the master products. Due to the large number of articles and suppliers and the resulting constant updates, product data is obtained directly from the suppliers, transferred to the system and compared with the database. In addition, descriptive texts for the master products are added and used for the print catalogs or output via the API interface.

Around 42,000 media assets with derivatives are maintained for the master products. Visual elements such as product images, application images, product drawings, symbols, manufacturer logos and videos can be added and then assigned to the product structure or marketing structure. Documents such as operating instructions or assembly instructions are also managed.

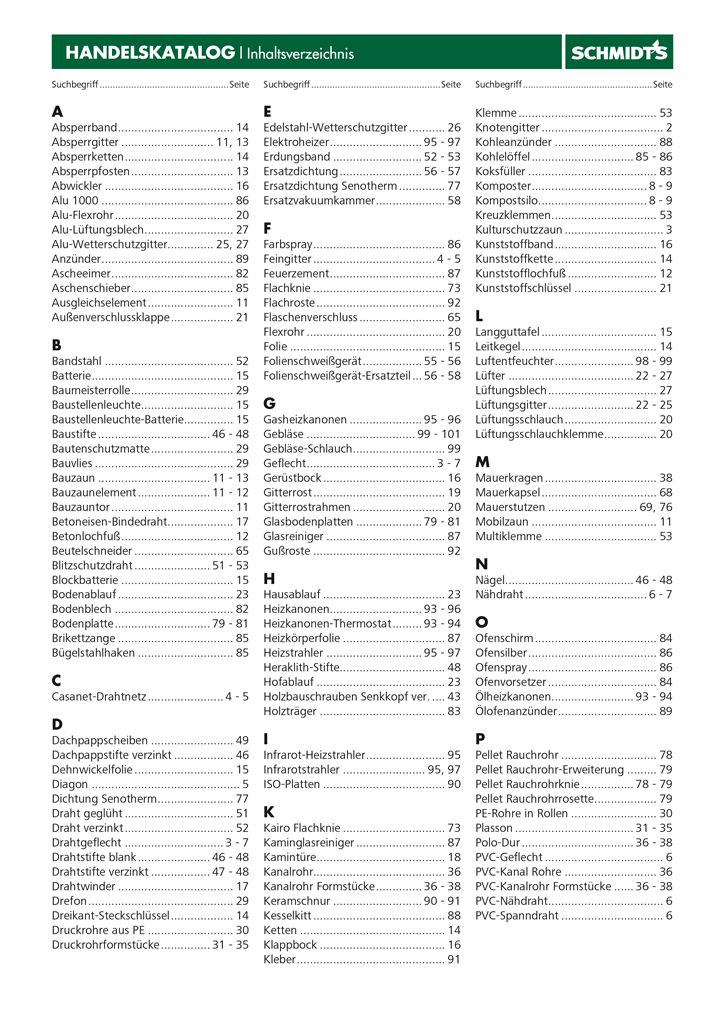

Another focus is print media production. This could be implemented quickly and easily with the crossbase solution, despite a demanding layout. In addition to the regularly produced catalogs and brochures, special customer catalogs with an individual scope and separate prices are produced for larger customers.

The catalogs contain between 50 and 500 pages, and the degree of automation is around 90%. Advertisements or image pages are sometimes integrated into the page flow as "interrupters". The product tables are created in one step using mass functions for all master products in a page flow. The creation of flow frames and universal tables with automatic table expansion and predefined attribute sets is also used. Matrix tables with automatic table expansion are also produced. When finishing the catalogs, either the Schmidt's layout or the Weyland-Steiner layout can be selected for the pages.

In the product tables, hyperlinks are dynamically set to the article numbers, which then refer to the Schmidt's online store or the Weyland-Steiner online store, depending on the finishing. These hyperlinks are displayed in the flip catalog. In future, the product tables will be created in a "general catalog" directly when the master products are created and reused in the "output catalogs". This further minimizes the amount of work involved in creating the catalogs and the production time.

Result

By implementing the crossbase solution, Schmidt's has significantly increased efficiency in catalog creation and product data management. It not only supports the company in catalog creation, but also revolutionizes the entire product data management, resulting in a significant increase in efficiency.

Advantages

- Centralized and structured management of over 200,000 articles

- Minimization of maintenance effort through the inheritance concept

- High degree of automation in catalog production (approx. 90 %)

- Dynamic hyperlinks to online stores in the catalogs

- Efficient maintenance of approx. 42,000 media assets

About Schmidt's

Founded by Josef Schmidt in Bludenz (Austria) in 1887, Schmidt's is one of the oldest and most successful hardware wholesalers in Europe. It is a full-range supplier of construction, civil engineering products, fittings, tools, machinery, factory equipment, chemical and technical products, workwear, fastening technology, gardening and power tools. Schmidt's employs over 700 people at 14 Austrian locations and is entirely family-owned.

Find out more about how Schmidt's uses the opportunities offered by crossbase: